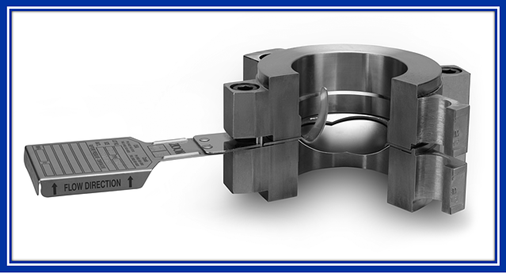

PRE-TORQUE HOLDERS ARE SUPERIOR TO STANDARD HOLDERS

They are designed with pre-set torque values to generate high clamping loads allowing the disk to be assembled conveniently in maintenance or instrument shops prior to field installation. Pre-assembly with the recommended torque load ensures proper engagement of the metal to metal “bite” type seal. Once assembled, the device can be easily installed in the field where the additional load of the companion flange bolting provides for complete functionality of the device.

WHY USE A PRE-TORQUE HOLDER? THE REASONS TO USE PRE-TORQUE HOLDERS:

- The pressure relief device can be removed for inspection and reinstallation without disturbing the seal integrity.

- Simplification of difficult rupture disk installation in locations where it’s problematic to remove the disk and holder separately from the flange.

- Standby disk and holder can be pre-assembled for immediate installation.

Consistency and ease of disk assembly installation leads to reliable and safe performance.